工艺流程

专统工艺与现代生产技术相结合

01

根据配方比例准备原材料

02

熔炼和甩片

03

氢破碎与气流磨

04

磁场内坯料成型与取向

05

烧结与时效

06

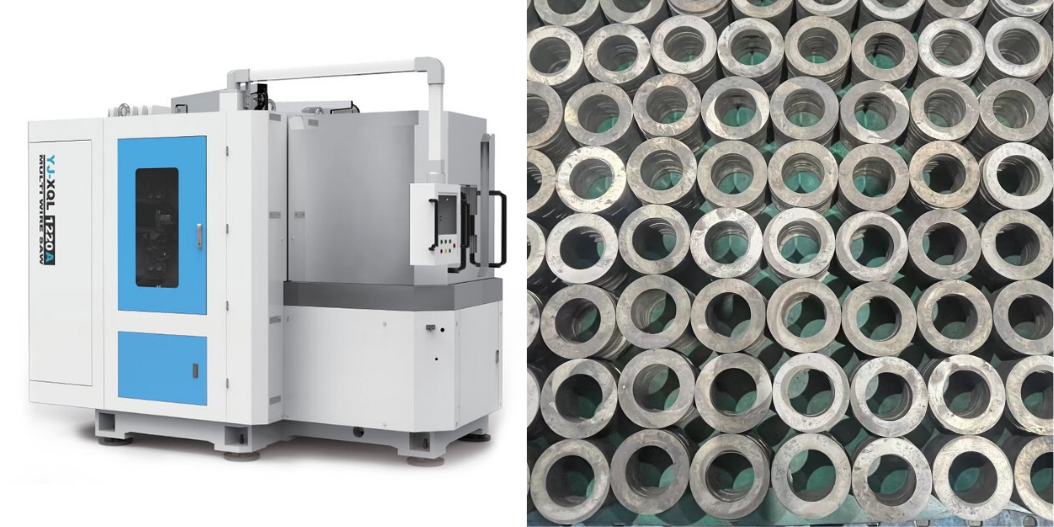

机械加工

07

电镀

08

产品饱和磁化

09

包装运输

IQC

分析合金结构与成分

检验颗粒大小与 粒度分布

检测毛坯尺寸与 垂直度

检测检测烧结后尺 寸与磁性能

检测尺寸精度

检测磁通

检测外观等

包装运输

工艺流程

01

根据配方比例准备原材料

IQC

02

熔炼和甩片

分析合金结构与成分

03

氢破碎与气流磨

检验颗粒大小与 粒度分布

04

磁场内坯料成型与取向

检测毛坯尺寸与 垂直度

05

烧结与时效

检测检测烧结后尺 寸与磁性能

06

机械加工

检测尺寸精度

07

电镀

检测磁通

08

产品饱和磁化

检测外观等

09

包装运输

包装运输

质量控制

质量目标

质量目标

≥98分

满意度

客户满意度≥98分

≤2件

客户抱怨

客诉抱怨每月≤2件

100%

良品率

成品出货良品率100%

100%

合格率

主要原材料抽检合格率100%

98%

98%

毛坯检查批合格率98%

≥98%

合格率

外加工批合格率≥98%

性能及参数

烧结钕铁硼材料物理性能

表面处理物理性能及使用环境

烧结钕铁硼磁性能参数表

| 条目 Items | 参数值 Parameter Values | 单位 Unit |

| 居里温度 Curie Temperature | 310~380 | ℃ |

| 回复磁导率 Relative Recoil Permeability | 1.02~1.05 | |

| 剩磁温度系数 Reversible Temperature Coefficient of Br (20~100℃) | -0.09~-0.13 | %/℃ |

| 内禀矫顽力温度系数 Reversible Temperature Coefficient of Hcj (20~100℃) | -0.4~-0.7 | %/℃ |

| 密度 Density | 7.50~7.70 | g/cm3 |

| 维氏硬度 Vickers Hardness | 550~700 | |

| 抗弯强度 Bending Strength | -0.09~-0.13 | MPa |

| 抗拉强度 Tensile Strength | ≥80 | MPa |

| 抗压强度 Compressive Strength | 800 ~1050 | MPa |

| 电阻率 Electric Resistivity | 150 | μΩ·cm |

| 热传导率 Thermal Conductivity | 8~10 | W/(M·℃) |

| 热膨胀系数 平行于方向 Coefficient of Thermal Expansion (Parallel to the orientation) | 5 | 10-6/K |

| 热膨胀系数 垂直于方向 Coefficient of Thermal Expansion (vertical to the orientation) | -1.5 | 10-6/K |

| 杨氏模量 Young's Modulus | 150~200 | GPa |

| 比热(20℃~320℃)Specific Heat(20℃~320℃) | 3.0~4.6 | J/(g·k) |

| 失重(低失重产品)weight loss(low weight loss products) | ≤2 | mg/cm2 |

| 种类 | 表面颜色 | 物理性能 | 使用环境 | 涂层厚度 |

| Coating Material | Colour | Properties | Environment of Application | Thickness of Coating layer |

| 电镀锌 | 蓝白色、黑色、彩虹色等 | 表面致密、稳稳定、均匀 | 具有较高的防腐能力 | 6um≤∮≤12 |

| Zine | Blue, Black and rainbow etc | Compact, Stable and Homogeneous | With reasonalbe capability of anticorrosion | |

| 电镀镍铜镍 | 银白色、黑色 | 镀层具有金属光泽、色泽均匀、表面清洁 | 适用于较为苛刻的环境中 | 15μm≤∮≤30pm |

| Nickel-Copper-Nickel | White and black | Light and Stable | Suitable for higher corrosive environment | |

| 磷化 | 浅灰色 | 厚度均匀 | 轻微防锈 | |

| Phosphorization | Colorless or light gray | Uniform thickness | Short-term anticorrosion | |

| 环氧 | 黑色、灰色、有一定光泽 | 涂层均匀,绝缘 | 适用于较为苛刻的环境中 | ≥15μm |

| Epoxy | Black and Gray | layer with certain luster, insurability | Suitable for higher corrosive environment | |

| 派瑞林镀膜 | 透明 | 厚度均匀、致密无针孔,绝缘 | 适用于极为苛刻的环境 | 0.1μm≤∮≤100pm |

| Parylene | Transparency | Uniform thickness, density pinholes- free and insurability | Excellent capability of anticorrosion especially for small items | |

| 镍+铜+环氧 | 黑色 | 涂层均匀,绝缘,稳定 | 适用于极为苛刻的环境中耐 盐雾>300hr | 10-30μm |

| Ni+Cu+Epoxy | Black | Layer with certain luster insurability and stability | Excellent capability ofanticorrosion. Suitable for hostile environment salt spray resistance>300hr | |

| 铝+环氧 | 黑色 | 涂层均匀,绝缘,稳定 | 适用于极为苛刻的环境中 耐 盐雾>650hr 适用于新能源骑车汽车产品 | 15-35μm |

| Al+Epoxy | Black | Layer with certain luster insurability and stability | Excellent capability of anticorrosion. Suitable for hostile environment Salt spray resistance>650hr Widely used in EV industry. |

| 牌号 Grade | 剩磁 (Br)KGs | 矫顽力 (Hcb)KOe | 内禀矫顽力 (Hcj)KOe | 最大磁能积 (BH)maxMGOe | Hk/Hcj | 最高工作 温度(T)℃ |

| N33 | 11.4~11.8 | ≥10.5 | ≥12 | 31~35 | ≥95 | 80℃ |

| N35 | 11.8-12.3 | ≥11 | ≥12 | 33~37 | ≥95 | 80℃ |

| N38 | 12.3~12.7 | ≥11.2 | ≥12 | 36~40 | ≥95 | 80℃ |

| N40 | 12.7~12.9 | ≥11.4 | ≥12 | 38~42 | ≥95 | 80℃ |

| N42 | 12.9~13.3 | ≥11.5 | ≥12 | 40~44 | ≥95 | 80℃ |

| N45 | 13.3~13.7 | ≥11.6 | ≥12 | 43~47 | ≥95 | 80℃ |

| N48 | 13.7~14.0 | ≥11.6 | ≥12 | 45~49 | ≥95 | 80℃ |

| N50 | 13.9~14.2 | ≥11.4 | ≥12 | 48~52 | ≥95 | 80℃ |

| N52 | 14.2~14.5 | ≥10.2 | ≥11 | 49~53 | ≥95 | 80℃ |

| N54 | 14.4 14.8 | ≥10.2 | ≥11 | 50~54 | ≥95 | 80℃ |

| 35M | 11.8~12.3 | ≥10.9 | ≥14 | 33~36 | ≥95 | 100℃ |

| 38M | 12.3-12.6 | ≥11.5 | ≥14 | 36~40 | ≥95 | 100℃ |

| 40M | 12.6~12.9 | ≥11.8 | ≥14 | 38~42 | ≥95 | 100℃ |

| 42M | 12.9 13.3 | ≥12.0 | ≥14 | 40~44 | ≥95 | 100℃ |

| 45M | 13.3~13.7 | ≥12.5 | ≥14 | 43~46 | ≥95 | 100℃ |

| 48M | 13.6~14.0 | ≥12.9 | ≥14 | 45~49 | ≥95 | 100℃ |

| 50M | 13.9~14.2 | ≥13 | ≥ 14 | 47~51 | ≥95 | 100℃ |

| 52M | 14.2~14.6 | ≥12.5 | ≥13 | 49~53 | ≥95 | 100℃ |

| 35H | 11.8~12.3 | ≥11 | ≥17 | 33~37 | ≥95 | 100℃ |

| 38H | 12.3~12.6 | ≥11.4 | ≥17 | 36~40 | ≥95 | 120℃ |

| 40H | 12.6~12.9 | ≥11.7 | ≥17 | 38 ~42 | ≥95 | 120℃ |

| 42H | 12.9~13.3 | ≥12.0 | ≥17 | 40 ~44 | ≥95 | 120℃ |

| 45H | 13.3~13.7 | ≥12.5 | ≥17 | 43~47 | ≥95 | 120℃ |

| 48H | 13.7~13.9 | ≥12.8 | ≥16 | 45 ~49 | ≥95 | 100℃ |

| 50H | 13.9~14.2 | ≥12.9 | ≥16 | 47~51 | ≥95 | 100℃ |

| 52H | 14.2~14.5 | ≥12.8 | ≥16 | 48 ~53 | ≥95 | 100℃ |

| 33SH | 11.4~11.9 | ≥10.5 | ≥20 | 31~35 | ≥92 | 150℃ |

| 35SH | 11.8-12.3 | ≥11.2 | ≥20 | 33~37.5 | ≥92 | 150℃ |

| 38SH | 12.3~12.6 | ≥11.3 | ≥20 | 36.5~40 | ≥92 | 150℃ |

| 40SH | 12.6~12.9 | ≥11.8 | ≥20 | 38~41 | ≥92 | 150℃ |

| 42SH | 12.9~13.3 | ≥12.4 | ≥20 | 40~44 | ≥92 | 150℃ |

| 45SH | 13.3~13.7 | ≥12.5 | ≥20 | 43~46 | ≥92 | 150℃ |

| 48SH | 13.7~14.0 | ≥12.8 | ≥20 | 45~49 | ≥92 | 150℃ |

| 50SH | 13.9~14.2 | ≥12.9 | ≥20 | 47~51 | ≥92 | 150℃ |

| 52SH | 14.2~14.5 | ≥12.8 | ≥19 | 48~53 | ≥92 | 150℃ |

| 30UH | 10.8~11.4 | ≥9.5 | ≥25 | 28~32 | ≥90 | 180℃ |

| 33UH | 11.4~11.8 | ≥10.3 | ≥25 | 31~34 | ≥90 | 180℃ |

| 35UH | 11.8~12.3 | ≥10.6 | ≥25 | 33~37 | ≥90 | 180℃ |

| 38UH | 12.3~12.6 | ≥11.1 | ≥25 | 36~39 | ≥90 | 180℃ |

| 40UH | 12.6~12.9 | ≥11.5 | ≥25 | 38~41 | ≥90 | 180℃ |

| 42UH | 12.9~13.3 | ≥11.8 | ≥25 | 40~43 | ≥90 | 180℃ |

| 45UH | 13.3~13.7 | ≥12.2 | ≥24 | 43~46 | ≥90 | 180℃ |

| 48UH | 13.7~14.2 | ≥12.5 | ≥24 | 45~49 | ≥90 | 180℃ |

| 50UH | 13.9~14.3 | ≥12.8 | ≥24 | 47~51 | ≥90 | 150℃ |

| 52UH | 14.2~14.5 | ≥13.1 | ≥24 | 48~53 | ≥90 | 180℃ |

| 30EH | 11.0~11.4 | ≥9.5 | ≥30 | 28~31 | ≥90 | 200℃ |

| 33EH | 11.4~11.8 | ≥10.3 | ≥30 | 31~34 | ≥90 | 200℃ |

| 35EH | 11.8~12.2 | ≥11.1 | ≥30 | 33~36 | ≥90 | 200℃ |

| 38EH | 12.2~12.5 | ≥11.6 | ≥30 | 35~39 | ≥90 | 200℃ |

| 40EH | 12.5~12.8 | ≥11.9 | ≥30 | 37~41 | ≥90 | 200℃ |

| 42EH | 12.8~13.1 | ≥12.2 | ≥29 | 39~43 | ≥90 | 200℃ |

| 28TH | 10.5~10.8 | ≥9.5 | ≥35 | 26~29 | ≥90 | 230℃ |

| 30TH | 10.8~11.4 | ≥10.1 | ≥35 | 28~31 | ≥90 | 230℃ |

| 33TH | 11.4~11.8 | ≥10.2 | ≥35 | 31~34 | ≥90 | 230℃ |

| 35TH | 11.8~12.2 | ≥10.6 | ≥35 | 33~36 | ≥90 | 230℃ |

| 38TH | 12.2~12.5 | ≥11.6 | ≥33 | 35~39 | ≥90 | 230℃ |

磁学常见问题

钕铁硼的镀层——派瑞林

兰诺磁业:以 “磁” 为约,暖冬启新,共赴新程

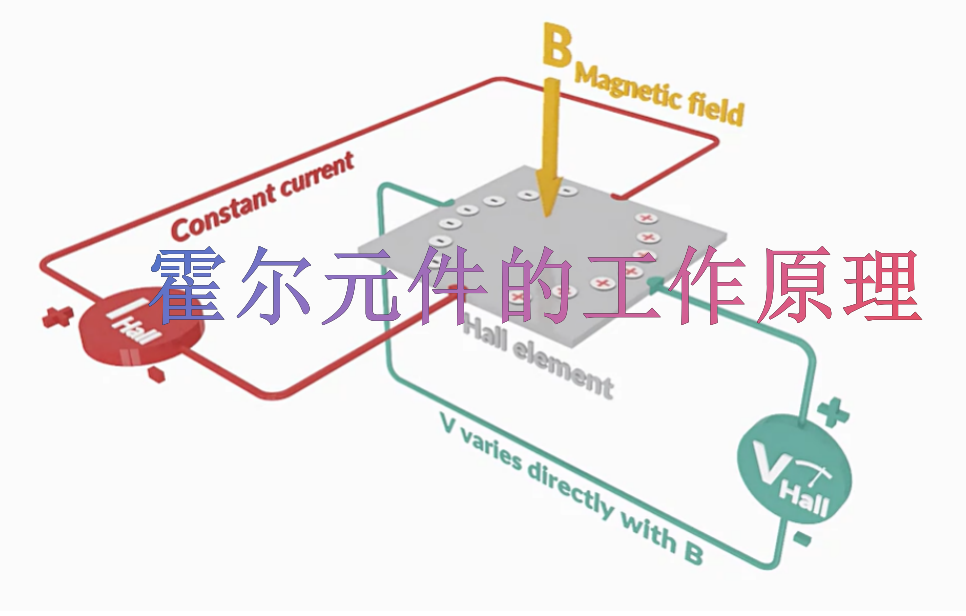

霍尔元件的工作原理

兰诺-无重配方磁钢研发进展

稀土永磁材料的涡流损耗

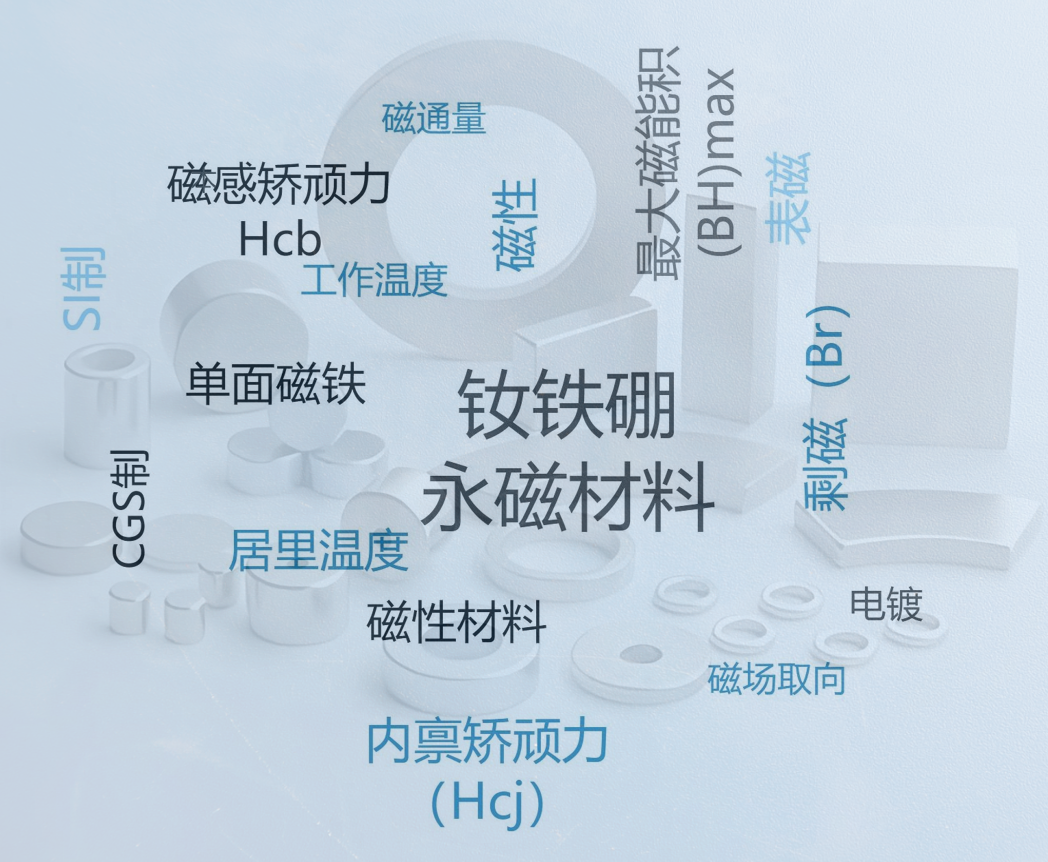

磁性材料入门

钕铁硼的尺寸与形位公差

钕铁硼的使用寿命—永磁体的长时间稳定性

常规工艺钕铁硼磁体和含铈磁体的差异

钕铁硼表面处理之—钝化

烧结钕铁硼的物理性能

3C产品中的钕铁硼磁钢

磁选机与永磁体

烧结钕铁硼多极充磁技术

什么是磁矩

烧结钕铁硼磁钢的取向与充磁

磁铁的吸力

烧结钕铁硼永磁体的牌号与性能

磁钢如何空运?

烧结钕铁硼的成型工艺

永磁材料大赏

永磁体的温度稳定性

退磁的三种方法

烧结钕铁硼牌号的含义

海尔贝克阵列

磁铁在喇叭中的应用

磁材的常见镀层

常见的新能源汽车电机

表磁、剩磁和磁通量

磁学常见问题